Craft a Stylish M&M Dispenser with Wood and Brass

Updated: April 2024

My dad LOVES peanut M&Ms, so I couldn’t think of anything better to give him than a sophisticated dispenser for his favorite candy. While looking for a gift to accomplish this, I saw Pneumatic Addict’s M&M Dispenser. My project is primarily based on hers (check out her article here).

Affiliate links are used on this page. See my disclosure page for info on affiliate programs.

Tools

Table Saw *

Jigsaw *

Chisel

Screwdriver

* I used these tools for this project, but I no longer recommend the Ryobi Table Saw or Jigsaw

Materials

1 - Cut Material Down to Size

I like to cut to length first. This lessens inconsistencies when ripping to the final width.

Once cut down, I rip the roughest edge off of the stock. I do not have a jointer, so I run the smoothest side against my table saw fence at a minimum distance to the blade.

With one side ripped square, I flip the piece to rip the other side to its final width. This second rip cut should remove more material than the initial squaring rip cut.

2 - Remove Candy Circle

Before drilling out the rotating candy dispenser, I used relative measurements to mark the face for cuts. These marks show where I will cut the sides, the open bottom, and the rotating circle. The sides and center will have continuous grain by cutting the entire face from one piece of wood.

Once marked, I used a hole saw to cut away the rotational component. The kerf of the hole-saw is large enough to accommodate the necessary rotational gap. When using hole saws, I like to drill a pilot hole where the center is. Once done, I can start the cut on one side and finish from the other. Switching sides to drill from and some tape keep the faces very clean.

To create a slot for the candy to sit in, I used a Forstner bit to remove the material. A drill press would be better for side cutting like this, but a drill works if you take your time.

3 - Cut Wood Grain Matched Face Out

I made the initial cuts with my table saw to keep both sides of the face parallel. This requires cutting, disengaging the power just before the final cut, and waiting for the blade to spin down before repeating on the other side. For stop cuts on the table saw, I always keep the piece perfectly still until the blade spins down.

Once both sides have been cut, the jig saw is used to finish all major cuts.

4 - Clean Up Cuts

The hole saw left a small ridge on the circle and sides. I used a rotary tool with a sanding disk to quickly sand the ridge flush with the rest of the piece.

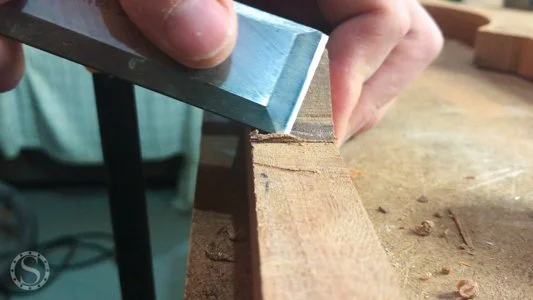

The jigsaw and table saw blade kerfs were not exactly the same, so there is another small ridge on the corners. For these, I used a sharp chisel to even out the surfaces. A chisel is a great tool for evening-out cuts and joints. I have a relatively cheap set, but I use them all the time.

Once the cuts had been cleaned up, it was time for some hand sanding. I only hand-sanded the parts that would be difficult to access once everything was glued up.

5 - Glue Up Body

It's time to start assembly! I used Titebond II for this since it will not be outside or exposed to high temperatures. A glue brush is very helpful to ensure the entire surface has glue applied to it.

I used all of my small to medium-sized clamps to keep the pieces from moving. The edges would be flush, and I certainly did not want anything to move around. Before the glue dried, I used a straw to clean the squeeze-out on the inside.

6 - Cut Head and Foot

Whenever possible, I prefer relative measurements to numeric measurements and markings. When sizing the footer, I knew I wanted its overhang to be equal to the material thickness. Instead of measuring the thickness and marking it on both sides, I used a cutoff to mark the measurements directly.

Once marked, I could cut to the line with my miter and table saws.

The header was sized and cut the exact same way, but the relative measurements were marked flush with the body.

7 - Route Chamfers

To ease the thick look of the header and footer, I decided to add a 45-degree chamfer to the edges. When I did this, I wore gloves, which is extremely dangerous! I learned from the Instagram community that this is a very bad idea after the fact. If you use a spinning tool like a router, don’t wear gloves.

When adding profiles on wood, I route the end grain first, then the face grain. The end grain tends to blow out a little. It will be cut away if it blows out on the face.

The chamfer lightens the overall look of what could be a blocky project and adds a little flair.

8 - Glue Foot and Sand

With the chamfers added, I could glue the footer to the base. I applied glue to the base since it would all touch the footer, but the whole footer would not touch the base. When an exact centering is needed for positioning, a tool like a combination square cannot be beaten. I also put a few clamps on it to make sure nothing moved.

9 - Cut Acrylic Sheet to Size

For the initial size of the clear acrylic sheet, I laid the piece on the front and marked the overhang with a Sharpie on the removable plastic. One great thing about working with clear material is the ability to mark while on top of other pieces.

Once cut to size, I used the same method to mark the opening for the candy to come through at the bottom. As with the footer, relative measurements are much better than measure and mark. The clear acrylic allowed me to mark with a sharpie and connect the dots with a straight edge.

I first attempted to use the “score and snap” method to cut the bottom opening out. However, for angled pieces, this did not work at all. Instead, I returned to my rotary tool with a cut-off wheel. The cutoff wheel made quick work of the opening and was more accurate. Just don’t be too aggressive with the cuts. The thin cutoff wheels tend to snap.

Since the screws that attach the acrylic to the base will show, I marked even spacing for them and drilled the final holes before continuing.

10 - Apply Finish

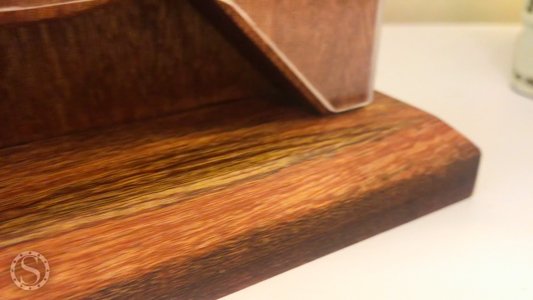

The finish must be food-safe because this is designed to be a peanut M&M dispenser. I have heard a few debates about what finishes are food-safe once cured. In this instance, I played it safe by using natural butcher block conditioner. The oil in the conditioner will make the wood grain pop, while the wax will provide an added layer of protection.

11 - Cut Brass Rod & Hinge

For the brass, I again used relative measurements. I wanted the brass to be roughly aligned with the front of the footer, so I marked the depth using the thickness of the header.

The brass rod and hinge were cut with an angle grinder. Both could have been cut with a hacksaw, but the angle grinder is significantly faster. Either method will require minor cleanup with some files.

The brass rod needs some polishing that would normally come from a lathe. I do not have a lathe, so chucking the piece up in my drill will have to do. Once in the drill, I started with a file to add a chamfer and rough out the piece. Next, I moved through sandpaper grits, starting with 250 and moving up to 2,000. The higher grits wipe away sand marks from the lower grits and add a nice polish to the metal.

12 - Add Center and Hinge

The brass rod will go in the center circle. Epoxy was used to make the bond permanent. Ideally, the surface of the brass would not be polished, but for this application, I think the bond will hold perfectly. I measured the indent in the body to mark the back indention before inserting it with epoxy.

The top was spaced slightly off the base using the thickness of the playing cards. This is my go-to method for spacing in most scenarios. With the top placed and spaced, I could add the hinge and mark locations for pilot holes.

If I were to do this again, I would use CA glue to fix the hinge in place before marking any pilot holes. Fortunately, it worked out, and the holes were in the correct spot. Once they were drilled, I could hand screw them in place.

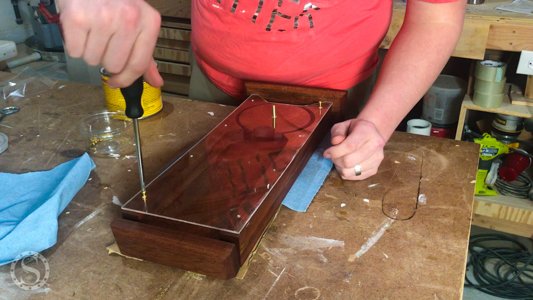

13 - Install Acrylic Sheet

The acrylic sheet was the final component of this build. Since the screws are all brass, I used a hand screw to install it. A power tool would strip the screw head immediately. With the screws installed, this project is complete and ready to be wrapped!

I am extremely happy with how this M&M Dispenser turned out. More importantly, my Dad loves it! This project was a great exercise in taking an existing project and adding your own twist. Thanks again to Elisha from Pneumatic Addict for letting me post my version of her awesome project. If you’re not following along with her work, you should be (check out her Instagram here).

This project was also a great learning experience for working with brass and acrylic. I love working with new-to-me materials and these were two very versatile ones to work with.

I would love to hear what you think about this project. Let me know in the comments on the video or over on Instagram.